Pingel Enterprise Drives Innovation In Precision Manufacturing

- Sep 22, 2024

- 4 min read

Pingel Enterprise, Inc. has been a cornerstone in the motor-sports industry since its founding in 1967 by Wayne and Donna Pingel. Starting as a small machine shop specializing in custom fabrication for "Chopper" motorcycles and rebuilding Harley-Davidson engines, Pingel quickly evolved into a renowned provider of high-performance components. By 1973, the company shifted its focus to manufacturing, gaining nationwide recognition from dealers and distributors for its precision-engineered motorcycle components. The company relocated to Adams, Wisconsin in 1979, allowing it to diversify and expand its offerings further.

By the 1980s, Pingel was outsourcing its valve production to a manufacturer using Brown and Sharpe machines, but the quality did not meet Pingel’s stringent standards. Deter-mined to control quality and enhance their products, Pingel brought manufacturing in-house in 1991. They invested in their first CNC machine—a Hardinge 2-axis lathe—and a Haas mill, becoming one of the early adopters of the Haas VF-2 series. However, realizing that one mill and one lathe would not keep up with growing demand, Pingel quickly expanded, acquiring four more lathes equipped with a 12-foot bar loader to automate operations and another mill fitted with a 3-piece rotary axis.

INNOVATION

Constantly seeking to be on the cutting edge of technology, Pingel made a strategic move in the early 2000s by investing in their first multi-axis turn/mill Eurotech machine, the 420 SLLY. This machine allowed Pingel to complete valve production in a single operation, a breakthrough known as “done in one,” which eliminated the need for additional milling work. This advancement reduced production time to an impressive 7 minutes and 35 seconds per valve, marking a significant leap in innovation for Pingel and solidifying their

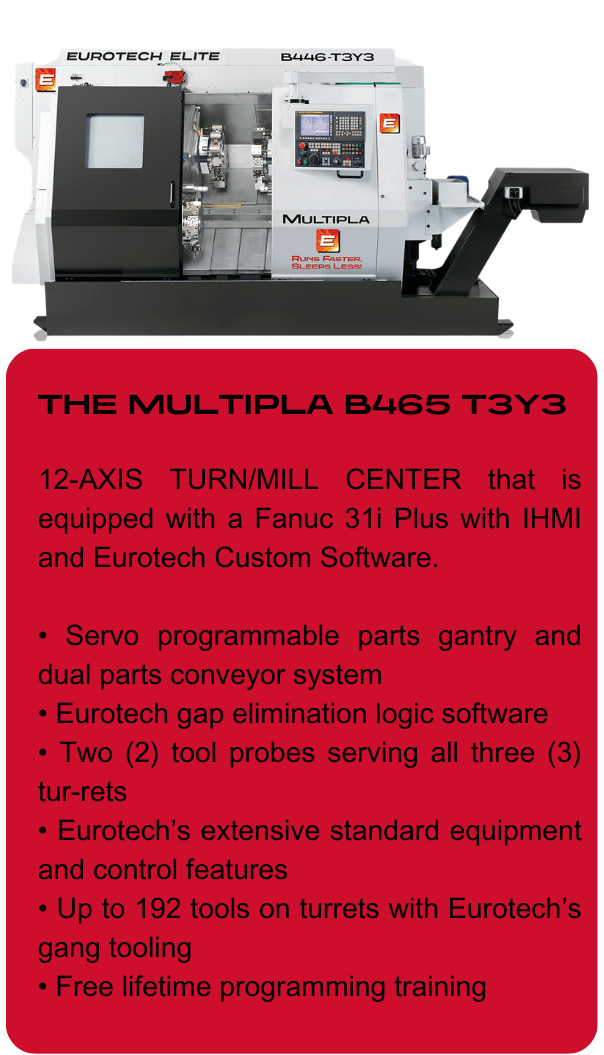

position as industry leaders. In 2021, the Pingel team, always looking to push the envelope further, considered the idea of purchasing a triple turret Eurotech (Multipla B465 T3Y3) to slash production time even more. After exploring various options at the IMTS in 2022, they partnered with Shane Jacobson, a service technician at Eurotech, who introduced them to Matt Woodcock from QMS, their local distributor. After carefully assessing their needs, Pingel invested in the Eurotech Multipla Triple Turret turn/mill machine."

Once the new Eurotech Multipla B465 T3Y3 turn/mill was installed, they immediately put it to work, programming it to produce their first valve. The result was a staggering reduction in cycle time to just 2 minutes and 35 seconds per valve... and the savings didn’t stop there...

“The Eurotech Multipla not only improved our set-up times, changeover times, and cycle times but also significantly enhanced the quality and finish of our parts,” said Steven Perik Jr., Pingel’s CAD specialist. “Since our parts are made from alumi-num and brass, achieving a polished finish before chroming is essential. With the new tooling and machinery, we reduced the polishing time from 5-10 minutes down to about 1 minute per valve."

TRAINING

To further optimize their operations, Pingel leveraged the expertise gained from a Eurotech macro programming class. This training empowered them to streamline their processes by consolidating 175 individual programs into a single, dynamic program using macro programming techniques. This approach allowed for quick and easy adjustments across all programs, dramatically reducing setup times and increasing machine capacity for additional jobs.

“With the time saved, we invested in a Royal Quick Change collet system and a top bar loader for the machine,” Steven continued. “The top bar loader automates channel changes, eliminating the need for manual adjustments and further enhancing the efficiency of our setup operations.”

ENGINEERING SOLUTIONS

“Our partnership with Eurotech has been pivotal in address-ing our challenges. The recent acquisition of the Eurotech B465-T3-Y3 machine, equipped with a Top Bar loader, is a prime example of this collaboration. This advanced triple turret twin spindle machine has allowed us to consolidate 175 separate programs into a single, user-friendly program, dramatically reducing setup times and cycle times by five and a half minutes per cycle. This optimization is crucial for a product they have been perfecting for over 50 years. Additionally, the precision tolerance and superior finishes provided by the B465-T3-Y3 have significantly reduced handling time for parts. Tasks that once required 5-10 minutes for polishing are now completed in just over a minute, ensuring that Pingel can meet the exacting standards of both their products and their customers.

INSTALLATION

“I was thrilled to be able to install Pingel’s latest Eurotech machines. It was like a homecoming as I was employed there when their first Eurotech hit the floor about 20 years ago. It is where I was first introduced to the Eurotech mill/turn line and fell in love with the brand as a setup operator. What an honor it was to be able to go back to Pingel and install one of our finest machines, catch up with my old colleagues and be a part of their successful journey.” - Shane Jacobson, Eurotech Service Technician

CONCLUSION

Walk into the pit area of any motorcycle drag strip, pick up any performance or custom oriented magazine and you'll find a Pingel® product there. Almost every drag and high performance enthusiast utilizes Pingel fuel delivery systems, and for good reason... the Pingel standard of quality and performance. Pingel Enterprise stands as a testament to the power of innovation and strategic partnerships in manufacturing. By embracing Eurotech's advanced technology, they have not only maintained their reputation for quality and precision but have also enhanced their competitiveness in the market. As they continue to push the boundaries of what’s possible in precision manufacturing, Pingel’s partnership with Eurotech ensures they remain at the forefront of the industry, delivering exceptional products to their customers and driving their success for years to come.

Comments