TURRET

Up to

BAR CAPACITY

Up to

"

Height of Centers

19.6 - 31.5

bed width

755

mm

No. of Guideways

Precision Perfected

• 3° Supporting Guideway

• Monolithic Structure

• Rotating Tailstock Quill

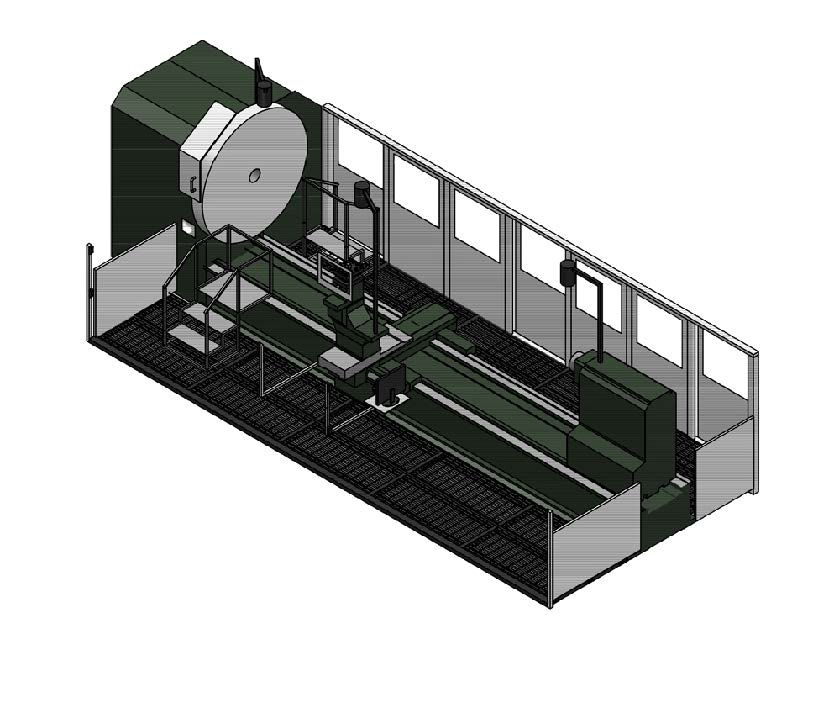

Monolithic structure, Fanuc control standard.

You can customize your machine with the support of our experienced team. Many different applications have been built such as grinding and railway applications. Finding you the best solution to your production requirement is built into our DNA and culture.

Customization and Flexibility

Heavy Cutting Capacity

The stiffness and strength of the beds, combined with a careful choice of power transmission, ensure high cutting capacity with any model.

Surface Finish

The Toro lathes offer a high-grade surface finish with a careful combination of quality components, frame rigidity, and power transmission design that guarantees the best result.

Control

The Toro series machines are equipped with Fanuc controls; however, many other brands are available. With each brand we are using a full package of components by the same supplier of NC, ensuring 100% compatibility.

Accuracy, Repeatability, and Reliability

The Toro series aligns and calibrates all lathe components such as the spindle, the tail stock, the carriage, and the tool post for one goal: matching the final dimensions of the workpiece with the intended dimensions.

Standard Equipment

• NC FAGOR or SIEMENS or FANUC or HEIDENHAIN

• Beds – Headstock – Tailstock – Carriages made of cast iron

• Monolithic structure

• Bottom supporting guideway (3° guideway)

• Automatic speed change gear box Baruffaldi with mechanic ratio 1:4

• Induction hardened and ground guideways with hardness 50-55 HRC

• Spindle line supported by high accuracy bearings

• Carriages are sliding on antifriction material

• High accuracy ground and certified ballscrews on X & Z (up to DBC 5000 mm); from DBC 6000 mm the longitudinal carriage movement is made by hardened and ground rack with inclined teeth, double pre-charged pinion and n. 2 servomotors

• Electric plant with low voltage control panel; it is placed in a suitable airtight cabinet. Make of components is Siemens and/or Schneider

• Automatic lubrication controlled by NC

• Enclosure with front sliding doors and work area lighting with led lamps

• Control programming panel, screen and handwheel mounted on a moving orientable arm (to place it on the best position for operator)

• Telescopic protections of cross slides

• Safety protections according EC standards

• Chip tanks on wheels

• Cooling system with electropump.

• Safety microswitch (to prevent collision) for X axis, Z axis and tailstock

• End-stroke for X/Z axis and tailstock

• Steady rest

• Tailstock with rotating quill

• Power displacement of tailstock along bed

• 3 Colours lighting

• Heat exchanger (for oil cooling in the headstock)

• Portable electronic handwheel

• Set of service tools and wrenches – Manual – NC programming manuals – Machine built according to EC standards

Delivers superior threading performance not commonly available from competing flat bed lathes - ideal for oilfield and power industry components.

Machines with up to 65 feet between centers and the ability to handle parts up to 90,000 pounds, making them the go-to solution for extreme part sizes and heavy-duty applications.

-

Additional guideways provide greater stability and support for the workpiece

-

Enhanced vibration damping ensures higher accuracy

-

Better load distribution extends machine life and cutting consistency

-

The structural integrity allows for tighter tolerances and smoother finishes even under the most aggressive cutting conditions.

Built for oil & gas, power generation, rail, shipbuilding, aerospace, and other large-format machining sectors.

Manufactured by our partner in Italy - known across Europe for quality, innovation, and performance.

WORDS FROM THE PRODUCTION FLOOR

The

ATL Heavy Plus

Discover

Lifetime

Training

Total Solutions

Get free lifetime training on the use of your machine, unique ways to accomplish complex production, and more.

GRADUATES INCLUDE

Get in Touch and Receive a Free Quote

(Time Study Included)

By submitting, you give Eurotech permissions to store and process your personal information so we can provide you with the content you’re requesting. For more information, please see our Privacy Policy.